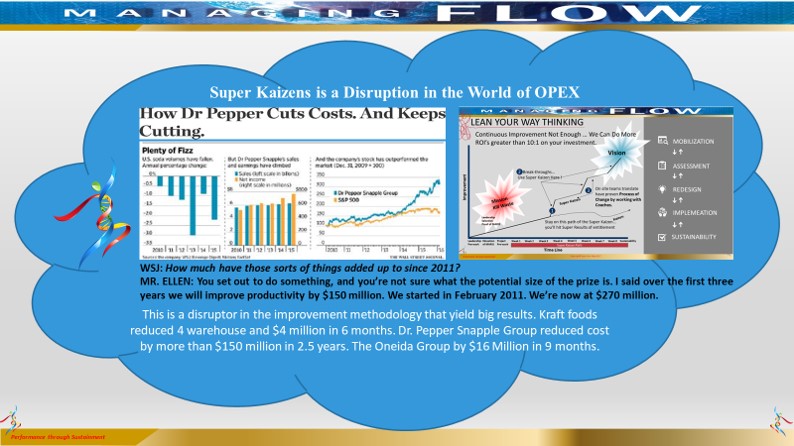

Super Kaizens are disruptive when coupled with new technologies.

Filed In: Industry News | Samurai Mindset

By John Ballis

“Show me someone who has done something worthwhile, and I’ll show you someone who has overcome adversity.“

– Lou Holtz

With the buzz word of “disrupting or disruption” in the business world they are leaping to the next landscape of technologies when Lean still has a big role to play.

I strongly believe in the importance of investing in organizational development through Lean tools to reduce waste.

The requirements of talent pools are changing faster each year. Continuous improvement can play a key role in coaching and training the next generation that not everything can be solved on an iPhone or Android. Yes, there is a lot that youth bring to the table. I call out business leaders not to lose sight of the fact that 90% of workflows are waste. It’s the CEOs of tomorrow that will engage their teams to understand before we simply start advancing with new technologies, we always must eliminate waste.

My tool of Super Kaizens is yielding super results in 8 weeks or less.

This in-depth 8-week coaching is designed to help equip participants with best of Lean and with speed to support Lean for the future. If you want to advance, I am excited to extend my Super Kaizen capability to support your Lean journey. Join me and learn these disruptive methods for Super results. Go to www.leanyourway.com

Comment sent via email.

Responding to a comment on my blog site.

What is the difference between a normal Kaizen and your super kaizen?

First of all, the VSM will determine the type of kaizen based on opportunity. A super kaizen involves 4-6 functions. For example, it may involve inventory reduction through a pull/Kanban system within the supply chain. That would include purchasing, materials management, finance, IT, and/or legal if you are reducing a warehouse.

It also may have IE’s involved in working with operators to reduce setups, improve flow, defect prevention and/or even artificial intelligence. They are usual a very large cost reduction in these events.

The best part is senior management participates during the per-work and full time on the implementation week. This show real engagement and creates accountability with employees. It should never be a headcount reduction. Let attrition be your friend.

Please ask more questions and I please comments here and on my blog site at johnballis.net

Contact John Ballis at johnballis@leanyourway.com

#leansamurai #opex #coaching #lean

I Implement Lean Manufacturing for Any Sized Project and AT Any Budget

If your organization can benefit from my expertise in assessing corporate culture, navigating organizational dynamics, and translating corporate strategies into tangible results for sustainable change, then you’ve come to the right place. I welcome the opportunity to get in touch for a preliminary analysis of your situation.

0 Comments