We Have Information Overload On the Subject of Continuous Improvement

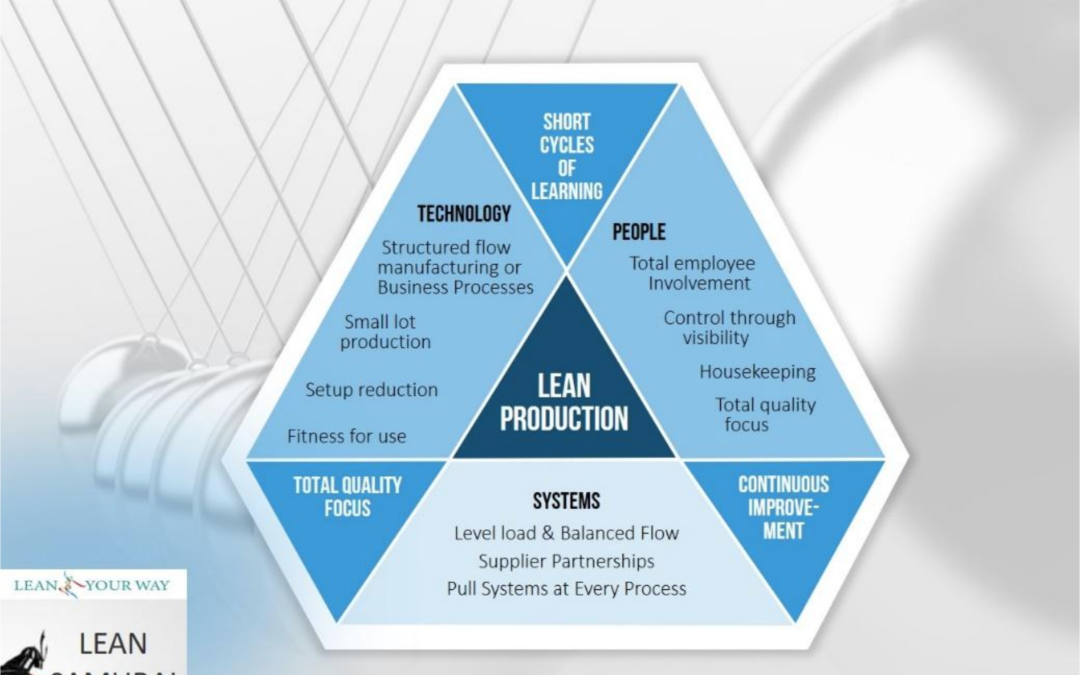

To quote Deming, “No Theory, No Learning.” Deming warns that people must fully understand the theory of a continuous improvement before they will embrace learning and apply the detailed tasks required to achieve it.

The Role of the Effective Lean Executive In the Lean Transformation Journey

In other Blogs, I have mentioned the aspects of ‘Lead & Drive’ vs. “Review & Control’ but have not expanded on the terms. Let’s start with Peter Drucker’s definition of the difference between efficiency and effectiveness. Efficiency is getting things done; effectiveness is getting the right things done.

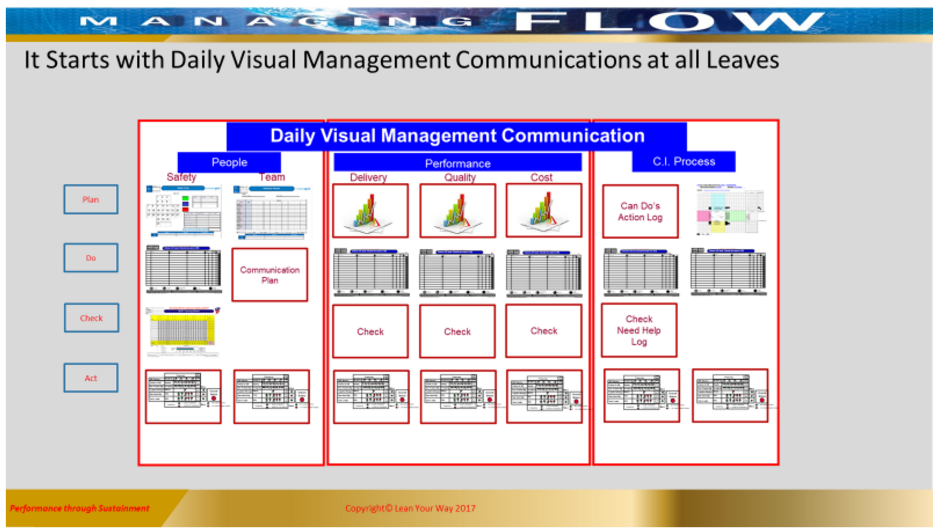

Visual Management Centers

Visual management tool of Lean is a hot topic. Should it be a digital format or a white board work center in a company? Visual management is different than just having a TV monitor or whiteboard on display. In this post I would like to show you the basic principles of creating visual management that call your teams to action. There is more to visual management than recording data. It’s what you do with it versus merely putting graphs together.

How 5S Can Be the Most Powerful Tool to Gain Cultural Buy in and Rapid Cost Reductions

5S is probably the most common lean method applied. It is seemingly simple, progress is visual, and it involves everyone. However, the average lifespan of a 5S effort is a less than a year. This is worse than doing nothing at all. Getting the organization to put this much effort into something and then not sustain it sends the unintended message that their efforts were not valuable. It is disrespectful.

Servant Leadership: Consistency Part 2

Tiger Woods Wins his 5th Green Jacket and 15th Major.

Recent Comments