“Show me someone who has done something worthwhile, and I’ll show you someone who has overcome adversity.“

– Lou Holtz

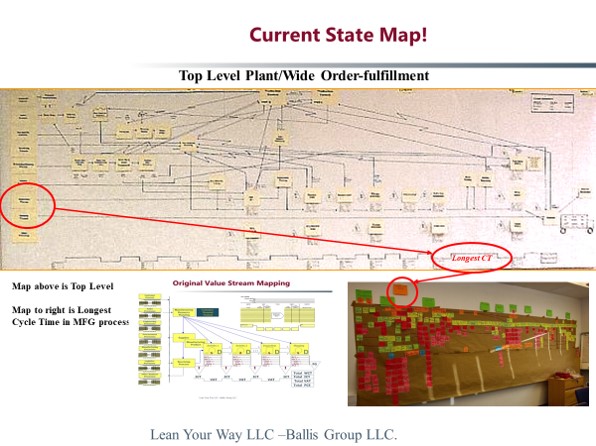

Original Value Stream Mapping

In the early days of Toyota, a SIPOC was a tool that summarizes the inputs and outputs of functions and process steps of the flow of the factory.

In the early days of Toyota, a SIPOC was a tool that summarizes the inputs and outputs of function or more process steps in the flow of the factory. SIPOC was originally create by Frank Gilbreft to members of ASME in 1921 as the presentation “Process Charts. Shingo used this to create the first value stream maps to identify waste.

Toyota used it to emphasize the needs of the customer foremost, the tool was called brown paper visual process flow and the process information is filled in starting with the customer and working upstream to the supplier.

The SIPOC today was often presented at the outset of process improvement efforts such as Lean, Six Sigma or Kaizen events during the “discovery or assessment” phases of the continuous improvement projects. On brown paper Shingo would build a SIPOC for each of the key processes. It would flow starting from top to bottom on the left-hand side of the paper from the raw materials to shipping department.

Then you would see the process steps for each one of the SIPOC’s flowing from left to right of those functions. Then it would capture the process times, defects, setup times, etc for each SIPOC. You would also see a timeline along the bottom representing the total cycle time of building a car. Tied together was the first Value Stream Maps.

Go to comments and I will publish your comments.

1 Comment

Submit a Comment

I Implement Lean Manufacturing for Any Sized Project and AT Any Budget

If your organization can benefit from my expertise in assessing corporate culture, navigating organizational dynamics, and translating corporate strategies into tangible results for sustainable change, then you’ve come to the right place. I welcome the opportunity to get in touch for a preliminary analysis of your situation.

This is the way I learned value stream mapping, except the process flows from bottom to top. It is my understanding that Shingo developed this as part of Kaizen.