“Show me someone who has done something worthwhile, and I’ll show you someone who has overcome adversity.“

– Lou Holtz

We Have Information Overload On the Subject of Continuous Improvement and a Rea lack of Lean Knowledge for Sustainability.

So, what happened? They all had good reasons for Continuous Improvement thinking.

- 79% of CEOs said the reason was to reduce cost of the supply chain

- 48% said to improve employee satisfaction

- 67% said to acquire other companies

- 89% said to increase customer satisfaction

- 74% said they were doing Lean to improve their profitability and market share.

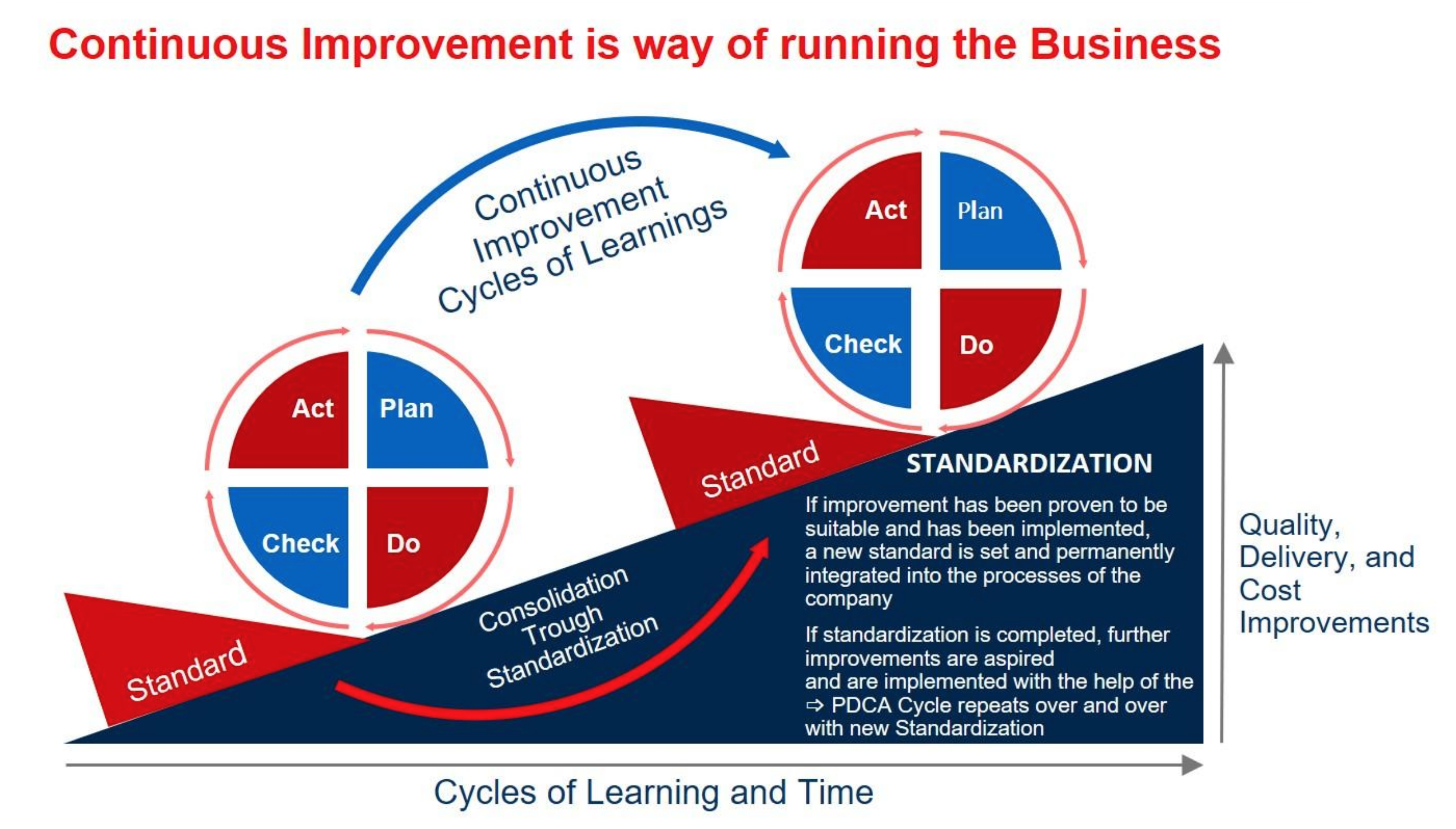

The reality is 91% of employees said there is a lack of learning cycles. In fact, these goals should have been attainable, but only 39% of CEO were satisfied with the pace of change.

So why weren’t these CEOs able to achieve their goals? Top 2 factors prevent real Lean implementation success:

- Lack of organizational readiness by Executives

- Lack of Lean knowledge

To quote Deming, “No Theory, No Learning.” Deming warns that people must fully understand the theory of a continuous improvement before they will embrace learning and apply the detailed tasks required to achieve it.

What is required is Cycle of Learning instead of certifications. Let me ask you this these questions:

- How many people has your company hired with Black Belt or Master Black Belt title that never implemented some of the basics of Lean or Six Sigma?

- How many projects or tools should BB or MBB must implement before you consider them an expert?

Please tell me your answers below, in the comments and I will publish your answer. Let’s stop the informational overload and start building real knowledge.

1 Comment

Submit a Comment

I Implement Lean Manufacturing for Any Sized Project and AT Any Budget

If your organization can benefit from my expertise in assessing corporate culture, navigating organizational dynamics, and translating corporate strategies into tangible results for sustainable change, then you’ve come to the right place. I welcome the opportunity to get in touch for a preliminary analysis of your situation.

John I agree. My experiences show that most six sigma projects are drawn out and often they mean never get full closure and realized savings. I am a fan of the PDCA. it has been proven out several times over and over again. I have had success with PDCA at several organizations – Danaher, Stanley Works and Goodrich to name a few. PDCA is back to basics.