“Even the proclaimed leaders of this lean movement document that only 4% of companies actually succeed in a lean transformation. Then we would assume 96% of companies who attempt this fail. However, these are myths and falsehoods that I intend to blow up.”

– John Ballis

What’s in the company name change? For more than 30+ years, the manufacturing world has been pursuing ways to improve their operations. Toyota has been leading the way with a great operational system that works for them. Even the proclaimed leaders of this lean movement document that only 4% of companies actually succeed in a lean transformation. Then we would assume 96% of companies who attempt this fail. However, these are myths and falsehoods that I intend to blow up. Lean Ballistics, formerly FlowCycle, are one and the same.

Here’s a quote from a good friend of mine who has been a lean practitioner and leader for many years. “The lean we all grew up with came to us completely wrong. Messages from Jones and Womack not only misled it, but misinterpreted.

In their roles as observed reporters, they described what they saw through an old management paradigm. They saw, interpreted, and documented everything from that perspective. They did that really well, and lean thinking became the go to manual as a result. However, it wasn’t the right thing, so they largely missed the engine of Toyota’s management system.” (Jim Hudson)

If companies are on a journey of continuous improvement, then they are not failures. I believe it’s time for businesses to understand their own DNA and create their own “Toyota” system. The goal of Lean Ballistics is to create a Futuristic Lean, that is, a Lean Your Way by mobilizing, assessing, redesigning and implementing a Lean business system based on the company’s unique DNA. It’s great to model after Toyota; however, it’s insane to think that you can lay the Toyota system over your business system and expect to have the same results as Toyota. Originality specifically tied to the unique character of each company is the way to create a successful and lean business system.

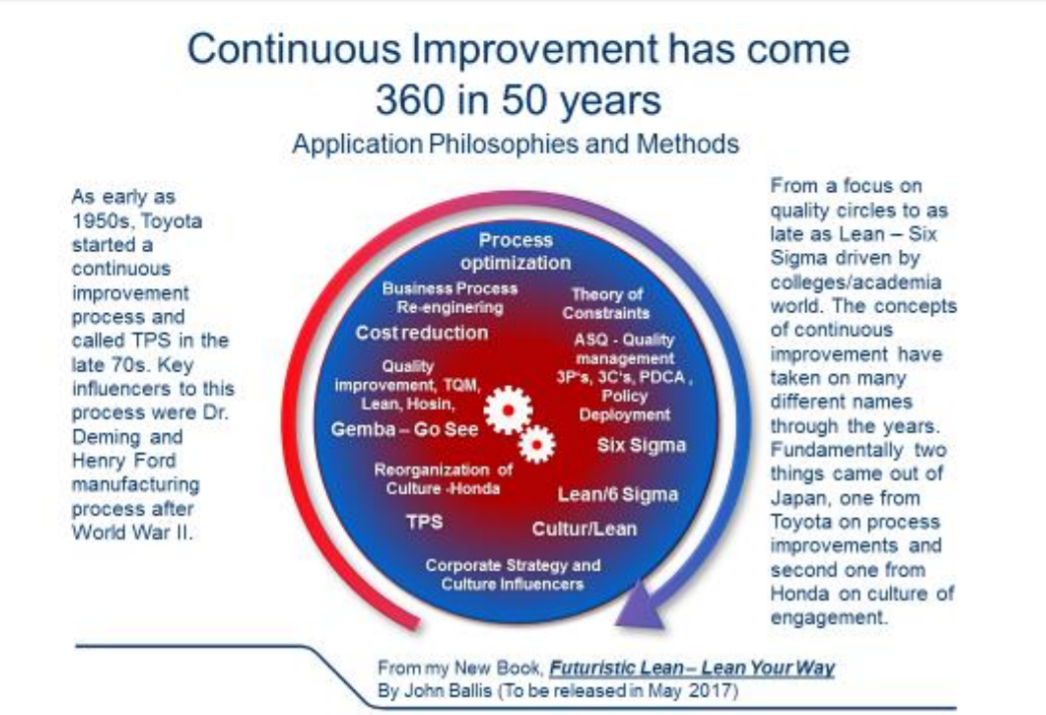

The academic world along with the top consulting firms keep reinventing the concept of continuous improvement. In the last 50 years we have come a full 360° in evaluating Toyota and all of the toolsets and philosophies related to continuous improvement.

In business today it’s almost a requirement for every leader and manager to understand Lean / Six Sigma. Leaders can benchmark to understand which tools are applicable for your business and identify projects to apply them to improvement to the bottom line. However, the truth is companies are not sustaining the investment they have made through continuous improvement. We define true sustainment as organizations that have a management change during the lean improvement process, and this lean journey is continued without interruption. Lean Ballistics company methodology and philosophy is building upon what a company has already started to ensure its sustainability through engagement of leadership and transformation of culture. We still believe every process has a flow; therefore, every process through people can be continually improved. We also believe that you must design a strategy connected to the company vision that energizes your employees to use the basics of Lean to improve on a daily basis.

The fundamental success of Lean / Operational Excellence Transformation does not stem from any one given Lean, Six Sigma, Kaizen Event or toolsets. It is the collective “cultural” system which integrates the strategic utilization of these tools through Lean Leadership and strategy that work within your company for the long term. Learn how a true “The Lean Way for your Company” must integrate a Culture, Leadership and Enterprise System in an effort to realize a total transformation. My next 4 articles will be about the top 4 reasons for failures from a survey of fortune 500 and 10,000 participants like yourself to ensure success.

Stay tuned.

John Ballis

Master Black Belt (MBB) 名人の

Samurai Master Black Belt (SMBB)家長

Author of Managing Flow – Achieving Lean in the New Millennium to Win the

Gold

1 Comment

Submit a Comment

I Implement Lean MAnufacturing for Any Sized Project and AT Any Budget

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.